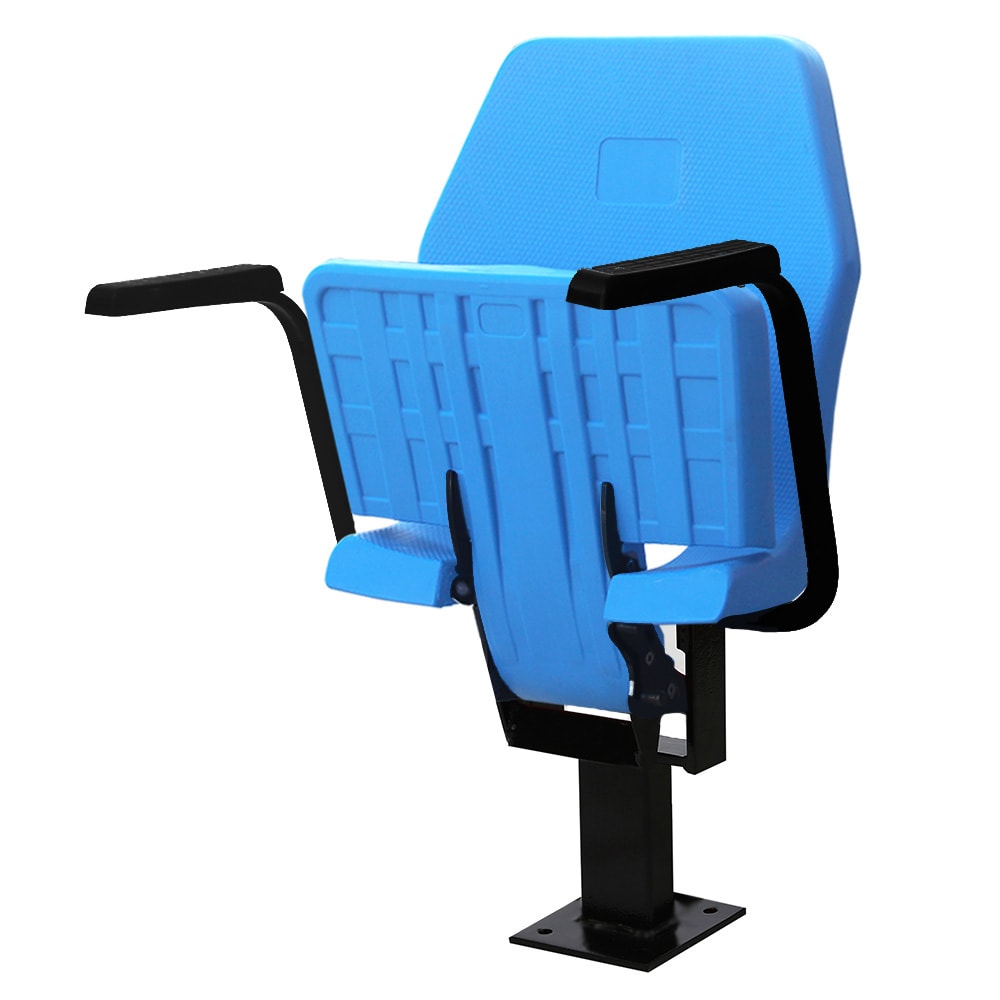

Perla Stadium Seat

It is completely produced by original ‘’Polyethylene Raw Material’’ with blow molding technique. There is no any non-standard (recycled) raw material inside Seat and backrest are with double walls and durable against impacts. In addition to that, there are ribs under the seat to increase durability. In order to make the seat more durable to UV and to the external factors, UV stabilizer additive is used. Color fastness dyestuffs are used is in maximum level in order to avoid discoloration. It is with TS EN 13200-4 and TS EN 12727 and TS EN 13200-4 certificates and production is made according to ISO 9001:2015 Quality Management System It has orthopedic seating feature and structure of legs and backrest is very comfortable. It is in a structure that pushes the body towards back side and has a design that prevents slipping while seated. Metal parts, composed of two components which are installed the seat and backrest produced by 5 mm thick plates . With these components, , seat and backrest connected to each other and 12 mm thick needle is used in this connection. Metal legs and connection parts are covered with electrostatic paint or galvanised. With this for long years corrosion is avoided. Features of the product can change according to the place and physical conditionsof the place. According to customer requests, our seats can be produced with UV Stabilizer Additives, Flame Retardant Additives, and Colour Fastness Additives . As it is folded through its center of gravity without a spring, there is no any malfunction in folding mechanism. It includes oval label place with size of 54x83 mm in front of backrest and it includes oval numbering place with size of 29x44 mm at the bottom of seating part that is seen when folded. The seat is installed to the floor and has 4 screw holes.

Sf786-ky Perla Stadium Seat Data Sheet

Sf786-ky Perla Stadium Seat Data Sheet